VIDEO CHECK ROLL CX (VCR-CX)

Small and compact videomicroscope, completely in aluminium, ideal to inspect flat and curved surfaces directly in the production cycle.

If used for the analysis of the surfaces of cylinders or rolls, its performances are exalted; it is mainly used in the check of the cylinders engravings in the graphic field as well as of materials in the metallography sector.

The VCR-CX supports two cold light lighting systems coaxial and annular. They are easily interchangeable, fed at 5V/12 V (like all the CX system), the issued cold light has a very high luminous intensity and is adjustable with continuous graduation in the annular system.

It can use all the optics with the magnetic connection of the VCR series (25X-2350X) plus a very high definition series, for particular applications.

A base full of precision mechanical stage with microshiftings on X-Y axis of 10mm guarantees an easy research of the target also for very high magnifications.

Two fixed support rollers, covered in an anti-slip material, allow a good stability on surfaces of cylinders having a minimum diameter starting from 60 mm with annular light and 120 mm with coaxial light; for lower diameters (up to 60mm) it is possible to use a different mechanical stage.

Magnetic rollers are also available for a steadier placing on surfaces which allow it.

The VCR-CX can be easily connected to a PC or a laptop through its 5Mpx USB camera and thanks to our Video View Basic software it can do measurements, comparisons, measurements and storage of the images directly.

For the using of the VCR-CX in particular applications, there are some stands available, which allow, opportunely equipped, to satisfy the most of the necessities.

KIT CONTENTS

|

Body for VCR complete of USB 2.0 CMOS 5Mpx camera (SPT DNS 000685) code SPT OVT 000698 |

|

Stand "CX" code STAND PCX 10446 |

|

CX Light code SPT OVT 000071 |

|

320X objective (field of view 0.85 x 0.64 mm) code 320-P |

|

USB cable code SPT OVT 013 4PNUSB (for USB 2.0 camera) |

|

Video View Basic software for the vision, acquiring and all types of measurements of the images code VVB 10395 |

|

Aluminium case for VCR Overall dimensions: 380 x 266 x 160 mm code VAL AMA 000212 |

AVAILABLE MODELS

| Camera | Software | Code |

| USB2.0 CMOS 5Mpx | Video View BASIC | VCR-CX D5K2 10562 |

OPTIONAL

OBJECTIVES FOR VCR-CX with Magnetic Mount

(Annular Light)

| Code | Video mag. |

Field of view | Min. examineable cylinder diameter [mm] |

| A-25 | 25X | 11.0 x 8.7 mm |  |

| D-50 | 50X | 5.5 x 4.2 mm | |

| F-75 | 75X | 3.6 x 2.7 mm | |

| G-100 | 100X | 2.7 x 2.0 mm | |

| H-150 | 150X | 1.8 x 1.4 mm | |

| ♦ 200-P | 200X | 1.3 x 0.98 mm | |

| ♦ 320-P | 320X | 0.85 x 0.64 mm | |

| ♦ 475-P | 475X | 0.55 x 0.42 mm | |

| ♦ 750-P | 750X | 0.35 x 0.26 mm | |

| ♦ 1100-P | 1100X | 0.25 x 0.19 mm | |

| ♦ 1500-P | 1500X | 0.16 x 0.12 mm | |

| ♦ 2350-P | 2350X | 0.12 x 0.09 mm | |

♦ Objectives that can also be used with coaxial light. Escursion on the Z axis of the VCR = 23 mm. Other objectives are available on request. |

|||

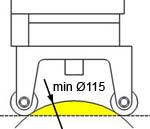

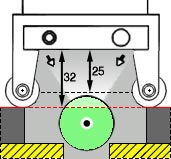

Note: It's possible to inspect cylinders with a diameter of less than 115 mm using suitable supports as in the examples shown in the "Roller Stand" section.

|

|

Click on the keys

|

||||||||||||||

| Every key of the keyboard, represents an image taken using the choosen magnification. | ||||||||||||||||

Practical example of employment of a VCR with PRISMS and STAND-UP

|

POSSIBLE APPLICATIONS

|

|

|

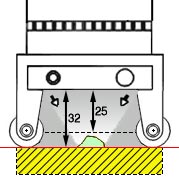

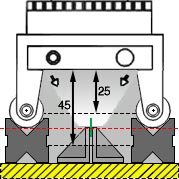

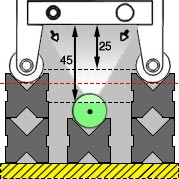

| Distance between the lighting source and the plane |

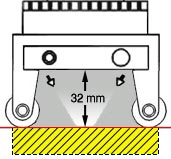

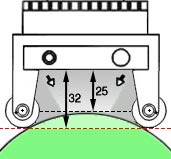

Best working distance between a cylinder's surface and the lighting source (Ø min 115 mm) | Position the cylinder must have when it has a diameter less than 115 mm |

|

|

|

| Objects' maximum height if placed on a flat surface: 7 mm | Position of the rising supports (prisms) for the inspection of objects with height between 12 and 32 mm | Position of the prisms for the inspection of objects with height between 42 and 62 mm |

|

|

|

| Inspections of multilayered sheets or of very thin profiles through the use of prisms and magnetic STAND-UPs |  |

Support (prism) for the inspection of small cylindric objects |

| For a correct illumination please refer to the following example | ||

|

||

| YES | NO | YES |

LIGHTING EXAMPLES

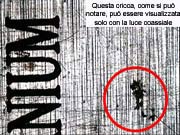

| ⇓⇓ Surfaces with Annular Lighting ⇓⇓ | |||

|

|

|

|

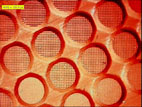

| Silk-screened plexiglass (200X) |

Chemically treated glass (320X) |

Anilox roll (1000X) | Rotochalcographic cylinder (750X) |

|

|

|

|

| ⇑⇑ Surfaces with Coaxial Lighting ⇑⇑ | |||

ANNULAR LIGHT

|

|

||||

|

|

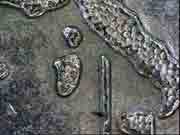

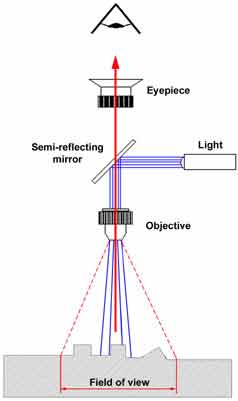

COAXIAL LIGHT

|

The lighting goes through the same axis of the lens. The light comes perpendicularly on the surface of the object creating a hard image; this is due to the complete return of rays coming from flat surfaces and of those reflecting from slanting surfaces. This system is perfect to visualize engravings of metallic objects. |

|||

|

||||

|

||||

OBJECTIVES FOR COAXIAL LIGHT with Magnetic Mount

| Code | Video magnification |

Field of view | Maximum examineable depth |

| 200-CX | 225X | 1.4 x 1.1 mm | 15 mm |

| 320-CX | 390X | 0.7 x 0.5 mm | - |

| 475-CX | 550X | 0.5 x 0.4 mm | - |

| 750-CX | 950X | 0.3 x 0.2 mm | - |

| 1100-CX | 1380X | 0.2 x 0.15 mm | - |

| 1500-CX | 1810X | 0.15 x 0.11 mm | - |

| 2350-CX | 2750X | 0.1 x 0.09 mm | - |

| - The values reported on the tables could be lightly different (5-10%) due to the optical and mechanical unlike series. - These objectives are usable also with VCR-CX PRO with annular light. |

|||

WORKING WITH "ANNULAR LIGHT PROFESSIONAL"

The possibility of inspecting any type of surface with all the wide range of available objectives of the VCR series (25X/2350X) and of the high definition series (LDH), will give a safe certainty to the operator to be able to use his device in almost all the occasions.

The difference between the set for annular light Professional and the annular light Lite one is the possibility, for the Professional, of selecting 14 different angulations of origin of the lightings around the subject so as to be able to search every particular and make the image visible and stereoscopic as in the example:

|

|

||

|

The use of the angulated light is suggested also to give prominence to the harshnesses or the conformation of the various surfaces.

APPLICATION EXAMPLES

Print screen (50X) |

Print point (200X) |

Print screen (200X) |

Flexographic cliché (25X) |

Anilox cylinder (1550X) |

Engraved plate for offset printing (320X) |

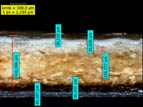

Section of milk's carton (320X) |

Section of business card (475X) |

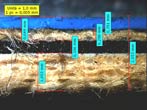

Section of rubberized cloth (printing cliché) (75X) |

Razor blade edge (750X) |

Rim of the razor blade examined with coaxial light (750X) |

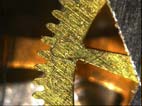

Watch mechanism (100X) |

Notes cardboard (50X) |

Notes cardboard (320X) |

White paper photocopy with traces of toner (320X) |